Strengthen operational resilience with agentic ITOps for manufacturing

Unify IT and OT with AIOps to prevent plant disruptions and protect OPEX costs.

Reduce downtime with visibility and analytics across corporate and plant operations

Unify IT and OT teams and tools with AIOps for manufacturing. Empower teams to quickly detect, respond to, and prevent issues to reduce maintenance and outage time.

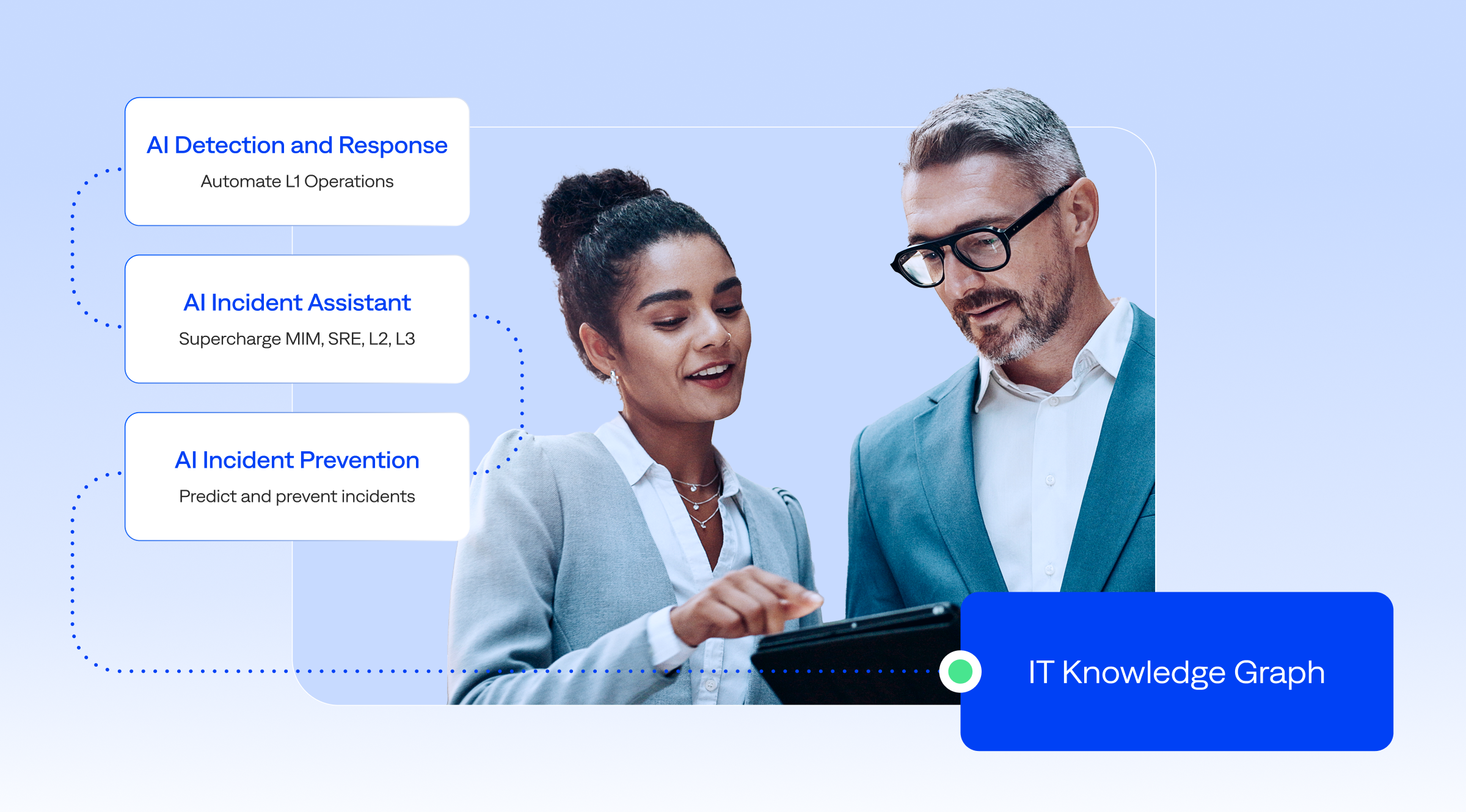

Accelerate IT incident detection and response

Correlate alerts across IT and OT environments with the BigPanda agentic IT operations platform and give manufacturing IT teams clear, actionable insights to triage and resolve incidents faster and minimize disruptions to production lines.

Facilitate predictive maintenance

Allow your teams to proactively identify recurring issues with Problem Management, prevent changes from impacting production lines with Change Risk Management, and reveal coverage gaps with Unified Analytics.

Improve decision-making

The BigPanda AI Incident Assistant transforms major incident response with automated workflows that reduce operator oversight and actionable investigation insights that allow teams to quickly make smart decisions that keep production lines running.

Prevent disruptions that impact production

Analyze data and patterns across incidents, changes, and IT/OT operational behavior. Identify emerging risks and enable IT for manufacturing teams to prevent disruptions before they impact output or quality.

The power of AIOps for manufacturing

“With BigPanda, our IT noise is not only reduced, but we are able to identify root cause in real-time- who the responsible team is, who owns the service that’s alerting, etc. which is significantly reducing our MTTR.”

“As we scale and grow the business, it’s integral for us to bring in automation and integration with other tools and technologies. My recommendation is, don’t wait to start your AIOps journey once you are overwhelmed with alerts.”

FAQ

How does BigPanda support IT/OT convergence in manufacturing organizations?

BigPanda unifies fragmented IT and OT data into a single platform, enabling ITOps for manufacturing teams to visualize dependencies across applications, equipment, networks, and plant systems. This helps manufacturers detect issues earlier, reduce downtime, and ensure both corporate IT and shop-floor operations stay aligned.

How does AIOps for manufacturing reduce unplanned downtime?

BigPanda agentic ITOps detects anomalies faster by correlating events from IT, OT, sensors, and industrial systems. BigPanda then surfaces probable root cause and impact areas based on historical incidents, helping IT manufacturing teams resolve incidents quickly and avoid cascading failures that can shut down production lines.

How does agentic AI-powered ITOps help incident response teams in manufacturing environments?

The BigPanda AI Incident Assistant analyzes operational data, historical insights, and institutional knowledge to automate major incident workflows, produce real-time, dynamic insights, and recommend remediation steps. This accelerates investigation for ITOps teams that manage manufacturing environments, where every minute of downtime affects output and OPEX.

Can BigPanda help manufacturing teams shift from reactive to preventive operations?

Yes, AI Incident Prevention from BigPanda can identify recurring issues, risky patterns, and system changes that are likely to cause future disruptions. This enables IT for manufacturing organizations to take action before equipment issues escalate and impact throughput, quality, or worker productivity.

How does BigPanda integrate with existing manufacturing systems and tools?

BigPanda connects your IT systems (legacy and modern monitoring tools, ITSM platforms, CMDB) with your OT systems (manufacturing execution systems, equipment sensors) using an open and agnostic integration platform. This enables manufacturers to modernize operations without replacing existing investments or compromising on visibility, and provides a unified view of all signals that impact AIOps for manufacturing and plant performance.

Check out more related content

Webinar

Reduce IT Costs: Save up to $13M with agentic ITOps

Discover how agentic ITOps enable enterprises to predict and prevent incidents before they impact customers.