Benefits

- Reduce costs: Unified OT/IT visibility and correlation eliminates manual investigation and enables faster resolution with fewer resources while minimizing impact to production lines.

- Support predictive maintenance: Advanced analytics surface recurring issues and identify coverage gaps, allowing teams to prevent equipment failures and reduce costly, maintenance-related downtime.

- Prevent disruptions: AI-powered analysis of change and historical incident data identifies the likely root cause and recommended remediation steps, enabling teams to make informed, swift decisions.

- Reduce regulatory risk: Operational and ITSM analytics detect issues early, enabling teams to maintain quality standards and support compliance and continuous improvement.

Manufacturers operate in complex environments where IT and OT must work in tandem to ensure uninterrupted production. However, many organizations still rely on decentralized ITOps, resulting in visibility gaps and fragmented data across sensors, cloud systems, and industrial applications. This leaves teams struggling to detect issues quickly, determine root cause, or understand production impact.

Downtime, whether planned or unplanned, directly affects revenue and customer commitments. With rising customer expectations, labor shortages, and aging equipment, operational reliability is more challenging and critical than ever. Without unified visibility, teams remain stuck in reactive firefighting instead of preventing issues before they escalate.

BigPanda helps manufacturers break this cycle. Our agentic IT operations platform unifies data across IT, OT, and industrial systems into a single, AI-powered source of truth. By correlating events, summarizing incidents, and surfacing emerging risks, BigPanda accelerates decision-making, reduces maintenance costs, and improves uptime to keep production running efficiently.

Manufacturers face challenges, including:

- Spiraling operational costs Manual workflows and disconnected IT/OT systems force teams to spend excessive time triaging alerts, researching root cause, and coordinating across silos. This inefficiency drives up labor costs, extends MTTR, and limits the ability to scale critical ITOps for manufacturing.

- Reactive maintenance Time is money on the production line. Any downtime, whether planned or scheduled, impacts output and revenue. Without proactive incident detection and predictive insights, teams often fail to discover issues until equipment or system failures have already impacted output.

- Revenue impact High incidences of unplanned downtime on production lines can result in significant financial losses and negatively impact production schedules and customer satisfaction.

How BigPanda can help

Agentic IT operations from BigPanda provide the unified visibility, automated intelligence, and actionable insights that manufacturing organizations need to operate with confidence.

By integrating IT and OT data sources from modern cloud infrastructure to equipment sensors and systems, BigPanda provides teams with a complete, contextual view of operational health. This enables enterprises to rapidly detect, respond to, and prevent issues before they impact equipment, applications, or production lines.

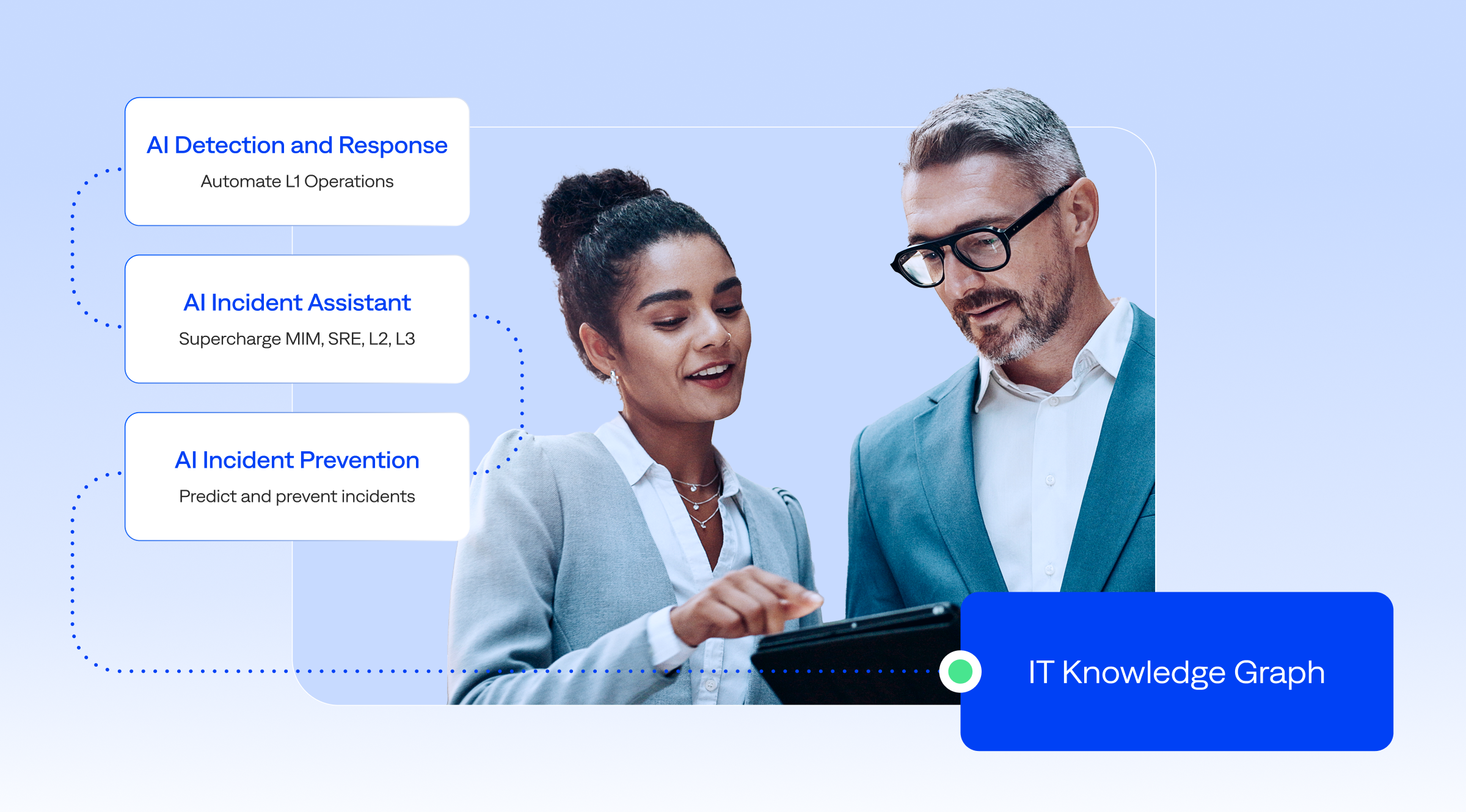

Using AI Detection and Response, BigPanda correlates operational data, service desk context, and historical insights to identify meaningful incidents, allowing teams to cut through noise and focus on the issues that matter. The BigPanda AI Incident Assistant provides operators and engineers with real-time summaries, change analysis, and recommended remediation steps, enabling them to investigate incidents more quickly and collaborate more effectively. And with AI Incident Prevention, manufacturers can identify recurring issues and high-risk changes before they disrupt production.

The result is faster incident response, decreased downtime, and improved resource allocation. Teams gain the ability to transition from reactive maintenance to proactive prevention, improving operational efficiency and ensuring production lines run smoothly. By providing a unified platform for manufacturing IT and operational teams, BigPanda enables organizations to reduce costs, enhance service reliability, and deliver consistent, high-quality output.

“As we scale and grow the business, it’s integral for us to bring in automation and integration with other tools and technologies. My recommendation is, don’t wait to start your AIOps journey once you are overwhelmed with alerts. Start early to get a single pane of glass to understand which monitoring tools you really need.”

Sanjay Chandra

Vice President of Information Technology

AI Detection and Response

AI Incident Assistant

AI Incident Prevention

Challenge

Business value

AI Detection and Response

Challenge

Business value

AI Incident Assistant

Challenge

Business value

AI Incident Prevention

Challenge

Business value

“With BigPanda, our IT noise is not only reduced, but we are able to identify root cause in real-time- who the responsible team is, who owns the service that’s alerting, etc. which is significantly reducing our MTTR.”

Priscilliano Flores

Staff Software Systems Engineer

Sony Interactive Entertainment